|

Value of Contract 7,007,643 K.D |

Date of Enterprise 15/08/1995 |

Date of Handing over 16/06/1998 |

Scope of Work

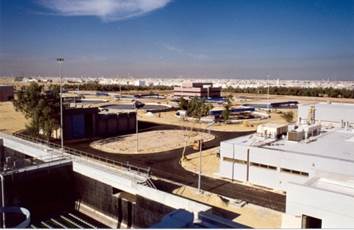

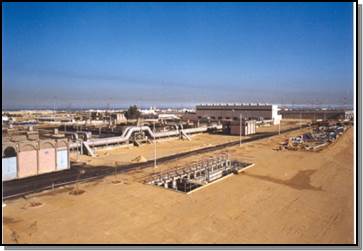

To be executed under this contract comprises the construction project of treatment unit processes, support buildings and all utilities and appurtenant facilities to Rerkka Treatment Plant. The existing treatment process will be maintained.

The following facilities will be constructed in the project: –

- Headwork’s facilities

- Primary Clarifiers – 4 –38m diameter primary clarifiers.

- Aeration Basins – 4 new aeration basins and modifications to the 8 existing aeration basins

- Two new Secondary clarifiers and 8 existing clarifiers will Be outfitted with new plow

- New return sludge pump station.

- Gravity Thickeners – 4-26 meter diameter

- Aerobic Digesters – 4 aerobic digesters

- Sludge Drying Beds – 30 individual beds totaling approximately 104.000 square meters.

- New Administration Building

- Compressed Air System * System DescriptionOne no. Electrical motor driven compressor generates the compressed air and is stored in a receiver of such capacity that prevents frequent cycling of the compressor, which is controlled by a pressure switch, on a start / stop sequenceThe discharge of the receiver is passed through a filter and a centrifugal dryer to remove the moisture from the compressed air supply.The pressure of the air supply is controlled by an adjustable pressure reducing valve, installed on the main line, the total length about 3500 M.L Stainless. Steel Dia 250-2500 mm

- Modifications to existing plant water system, from D,I. pipe all around the site the approx. totaling length about 21000 M.L dia. Between 75 mm-1600 mm.

- Modification of Storm System

Storm water drainage system is designed to collect, carry away and dispose off the following:- Rain water discharge on the roofs and floors of buildings.- Rain water discharge on promenades, car parking areas and streets.- Sub-soil drainage from sand pits and planters.- Waste water discharge from buildings, water storage tanks and plant rooms.The site storm water drainage system is connected to the existing box culverts passing in the vicinity of the site. - Modification of Fuel System2 Nos. of 24 kg LPG cylinders are arranged at the store of the Administration Building.One No. gas detector and control panel in the gas room which will annunciate gas concentration in the room above a preset level. This system shall automatically switch the room ventilation fan to a higher speed, thereby reducing the gas concentration in the room.Gas manifold shall be fabricated from black steel pipes and fitting and shall have welded joints. Tap offs to each cylinder shall be fitted with one check valve and one ball valve and shall terminate with a hose adaptor.

- Modification of Sanitary SystemSanitary drainage system is designed to collect, carry away and dispose off the discharge from the sanitary fixtures in the buildings.The site sanitary drainage system shall be connected to the new lift station and sewer than shall be discharged to headwork building using raw wastewater force mains as shown on the drawing. The totaling length about 2000 M.L dia 200 mm

- Modification Irrigation SystemIrrigation System is desired to caver the all plant area, consisting of H.D.P.E pipes 600 M.L dia. 1000-3000 mm- U.P.V.C pipe total 11000 M.L dia. 25-250 mmMajor Items Str. Excavation Plain Concrete Reinf Concrete. Stainless steel Pipes 1200 mm Dia. D.I. Pipes 75-1600 mm Dia. & Fittings HDPE Pipes 1000-3000 mm Dia. U.P.V.C Pipes 25-250 mm Dia. Drainage G.R.P Pipes